Filtration

Particle filtration is done with patented lamella filter elements. The elements are constructed of filter lamellas through which the oil is pressed and particles stick to the periphery of the filter element. Degree of filtration according to ISO 4406, code 16/14/13.

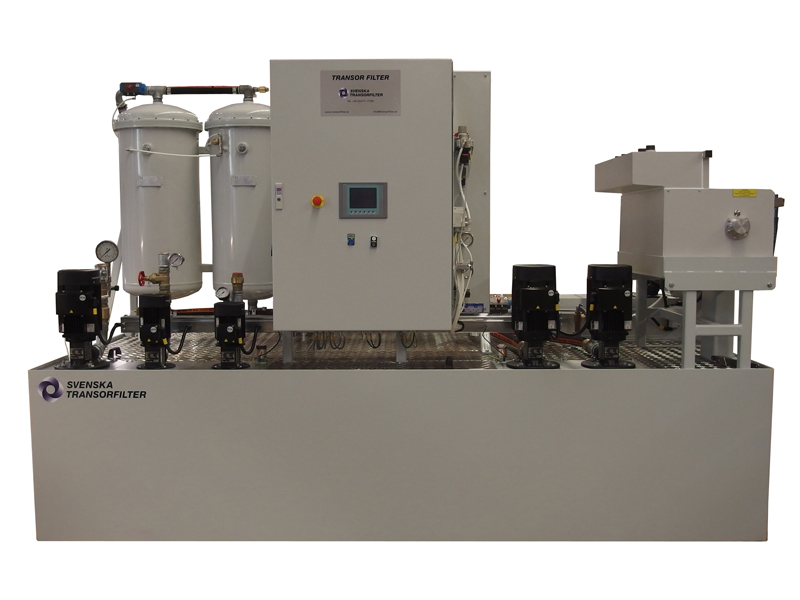

Filter elements are mounted in filter vessels which are divided into different groups. The filter groups are automatically cleaned with a built-in backwash system by blowing compressed air through the element and leading filtered particles to a sludge handling equipment. Under normal conditions, the lifespan of the filter element is up to 15,000 hours.

Function

The filter systems are PLC controlled and can be run individually connected to the grinding machine / EDM filter and/or to the factory control system for control and monitoring.

The flow of oil in a Transorfilter:

Contaminated oil from machine is led to a return oil tank. Then the oil is filtered in the filter vessel and ends up in a clean oil tank. The clean filtered oil is finally pumped out to the machine.

The filter vessels backflush automatically at intervals of 4 to 6 hours. Removed filtered particles are then led to a sludge handling equipment. Backflushing takes normally about 5 minutes. During that period the filter delivers oil from the clean oil tank without interruption.

Quality

Transorfilter filter systems are designed with proven technology and approved components. Our systems come CE-approved with user-friendly manual / documentation. All units are tested and approved according to test protocol values before delivery to the customer.

Advantages

There are many reasons why cutting oil with a high grade of purity is preferable. You find some of the advantages with Transor filtration below.

- No grinding waste affecting spools, spindles, valves, etc.

- Minimal machine maintenance.

- No interruption for sludge removal.

- The system eliminates filter cartridges, paper rolls or other filter media.

- Continuous filtration during backflushing. No downtime for filter maintenance.

- Cost of handling and disposing oil drenched waste decreases significantly.

- High precision and short cycle times results in increased productivity.

- Clean oil results in clean work pieces immediately after the grinding process.

- Shorter setup time due to cleaner machine.

- Contributes to an improved working environment due to less oil drenched waste.

- Clean oil means virtually non-existent risk of bacterial growth.

- Clean machine windows bring a good view of the grinding operation.

- Greatly reduces risk of machine/equipment damages due to less particles in critical areas.