Product Description

– Handling instructions for operation/maintenance of cleaning machines are supplied.

– Documents of the components for the machines are supplied.

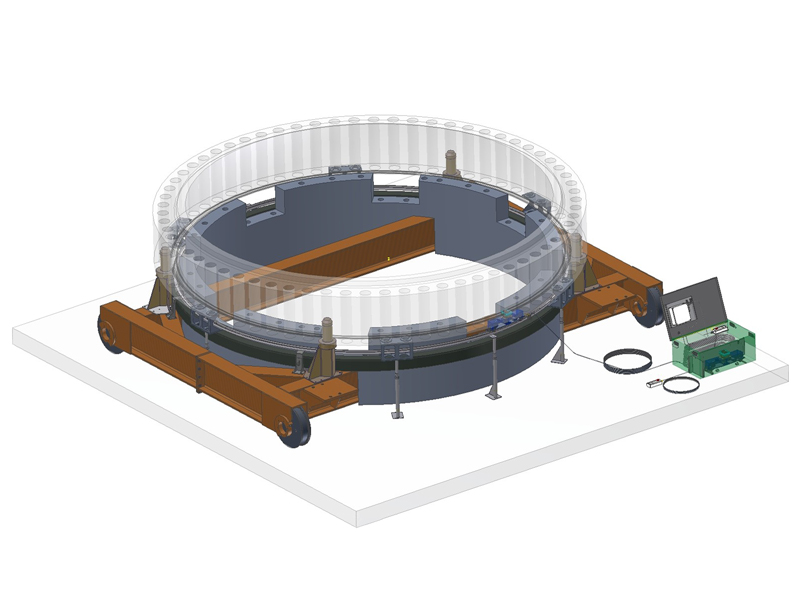

– The machines should be able to perform cleaning as per customer requirements such as sealing surfaces.

– The machines must not damage the sealing surfaces during cleaning.

– All components are secured so that they cannot come off during cleaning.

– The machines are sealed against the sealing surface so that particles are collected and not spread outside the machine.

– The control cabinet is equipped with an emergency stop.

– The cables for the machines can be supplied in a single package (wire loom).

– It is easy to change the cleaning unit on the machines.

– Cleaning media for the machines are provided by us.

– Machines and control cabinets are supplied in a carrying case (usually aluminum).

– The machines are equipped with carrying handles for easy lifting of the machine to and from the surface to be cleaned.

– Cleaning machines are adaptable to most nuclear power plants. We can also assist customers with the design of both rigs and mockups.

– All of the Transorfilter Sweden supplied machines are tested before shipment.

– Cleaning machine is kept in a shipping box in aluminum when not in use. Also the control unit and air supply are situated in the aluminum box.

– Associated rail assemblies, brackets and struts are supplied from the factory lying in packaging. Packing is sufficient for common ground transport in a truck.